Minimise unplanned expenses and ensure high quality

Minimise unplanned expenses and ensure high quality

Minimise unplanned expenses and ensure high quality

DRY DOCKING

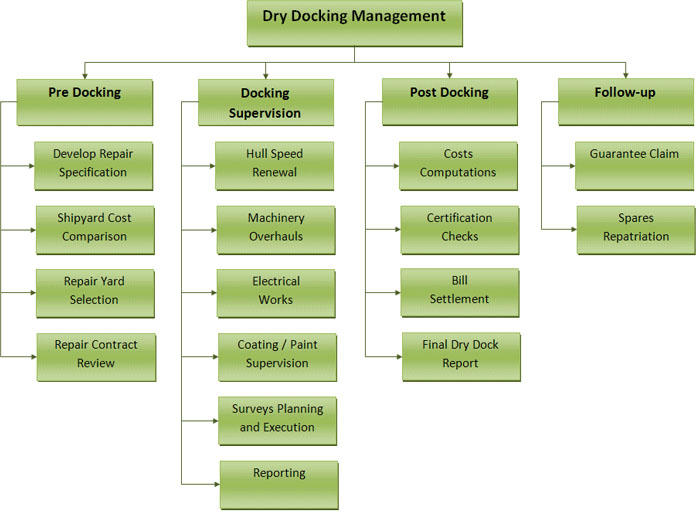

With professional planning, preparation and execution, we make dry docking predictable and efficient.

Every vessel is required to dry dock at least once every 5 years. The duration of a normal dry docking project is 10-14 days. If dry dock is poorly managed, the expenses and time can escalate and important defects may not be identified and corrected.

We identify objectives by engaging stakeholders, preparing comprehensive specifications and executing the project according to plan. This way, we minimise unplanned expenses and ensure high quality.

Influence with shipyards

• Improved quotation (Cost & Time)

• Priority for dock space

• Better influence on outcome

• Single point of contact for shipyards management

Continuous improvement

• Accumulative knowledge and experience to benefit our clients

• KPIs

• Valuable database

Project management competence

• Developed competence through training and experience

• Core work is docking by usage of software

• Digital and prompt reports guaranteed

AL KHAIR SHIPPING MANAGEMENT (AKSM) offers a dedicated & qualified staff consisting of Ex-chief engineers, Shipyard production engineers, coating inspectors, certified steel inspectors and electrical inspectors to ensure a safe and economical dry docking of their vessels.

• Dry-dock management responsibility at a single point

• Releases clients staff from being based for long periods at the repair yard

• Vessel superintendent in turn is able to concentrate on critical and operational issues affecting the other vessels under his charge

• Reduce workload on Superintendents

• Bring in expertise depending upon severity of task

• Experienced specialist staff bring in savings to client

• Effective cost control and reporting

• Prepare repair spec

• Comparison of costs

• Specialist service

• Expedite logistics

• Arrange surveys

• Work done reports

• Schedules

• Costs incurred

• Surveys carried out

• Spares and stores

• Lubes and hydraulic oils

• Any other issues that may impact dry docking budgets